What is laser marking? Definition and characteristics

Laser marking is a way to permanently mark an object with personalization and coding, both for safety and quality control reasons. It is a highly appreciated solution for its flexibility, reliability in yield and savings. It is particularly adopted for engraving metals but it is also indicated for marking wood and thermoplastic materials. There are several techniques in laser marking: surface and sub surface engraving, ablation, annealing, carbonization, foaming and color change. Small, medium and large companies use laser technology in manufacturing and supply chain processes as it represents a solution for companies for practical and innovative marking. Let's see together what the processing consists of.

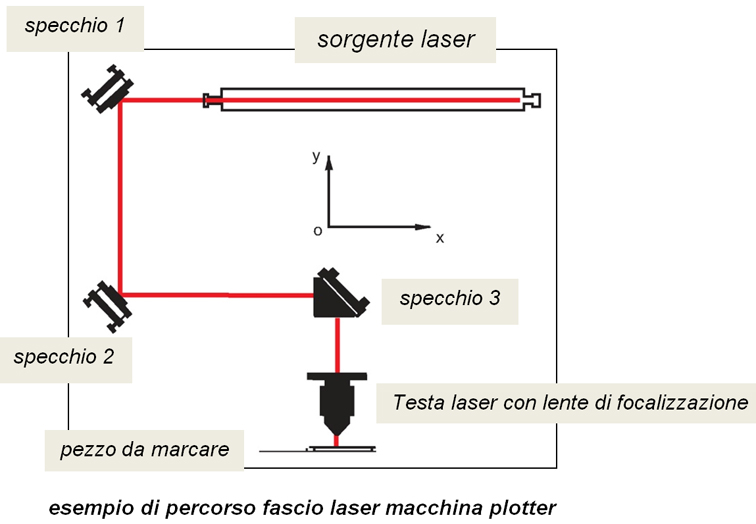

During the process, an intense laser light beam is focused on the surface of a piece. By piloting this point with moving mirrors or with a plotter head on the surface to be machined, the laser beam can create the image. Depending on the characteristics of the laser source, an instantaneous peak power density of several hundred kilowatts is delivered to the target causing an instantaneous modification of the surface. More details on how laser markers work.

The advantages of laser marking

Laser marking has several advantages, which is why it is preferred in the production and coding of different materials to create logos, alphanumeric codes for packaging or for traceability on packages and objects.

First of all, it uses a technique that does not require the use of inks, masks, solvents, acids, nor does it require tools that come into contact with the surface to be engraved. These properties distinguish laser engraving from alternative engraving or marking technologies in which inks or tools need to be replaced regularly.

Many engraving techniques cause the removal of a part of the material when it is engraved, the laser engraving does not cause the removal of material. The laser is used to create a change in the color of the material, resulting in a visible, practically indestructible brand with minimal impact on the object.

The environmental impact of laser markers is low, since the technology does not use inks, solvents or other consumables. By adopting laser technology, environmentally sensitive companies achieve eco-compatibility and cost savings with laser solutions.