News

Industrial marking's types

The industrial marking field is a rapidly evolving technology sector, essential for ensuring traceability, safety, and quality in the manufacturing world. In this article, we will explore the different types of industrial marking, highlighting the innovative solutions we offer and their respective advantages.

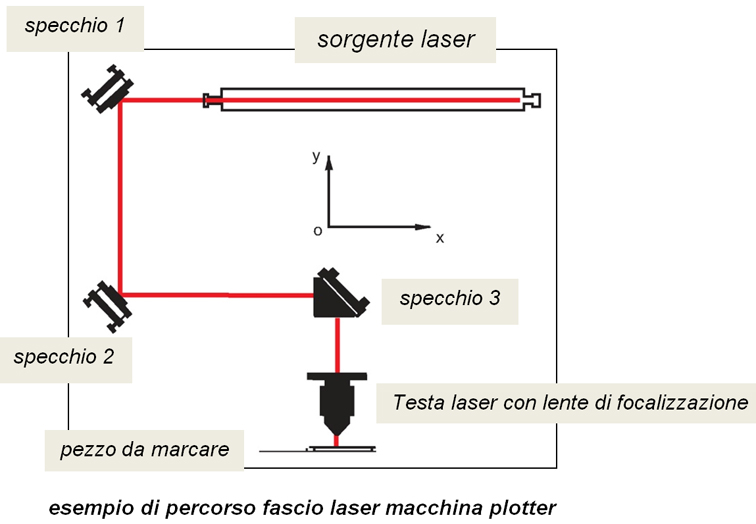

What is laser marking? Definition and characteristics

Laser marking is a way to permanently mark an object with personalization and coding, both for safety and quality control reasons. It is a highly appreciated solution for its flexibility, reliability in yield and savings. It is particularly adopted for engraving metals but it is also indicated for marking wood and thermoplastic materials. There are several techniques in laser marking: surface and sub surface engraving, ablation, annealing, carbonization, foaming and color change. Small, medium and large companies use laser technology in manufacturing and supply chain processes as it represents a solution for companies for practical and innovative marking. Let's see together what the processing consists of.

EPAL pallets, tracking and sustainability in logistics

Europe has noted that packaging is a steadily increasing source of waste. In 2018, it generated a revenue of 355 billion euros in the EU, and its volume grew from 66 million tons in 2009 to 84 million in 2021. That year, European citizens produced 188.7 kg of packaging waste per capita, a quantity that, without new measures, is expected to rise to 209 kg by 2030.

Benchtop Laser Markers: security

Benchtop laser markers have become increasingly popular in recent years due to their versatility and ease of use. However, not all products on the market meet the safety standards required by Italian regulations.

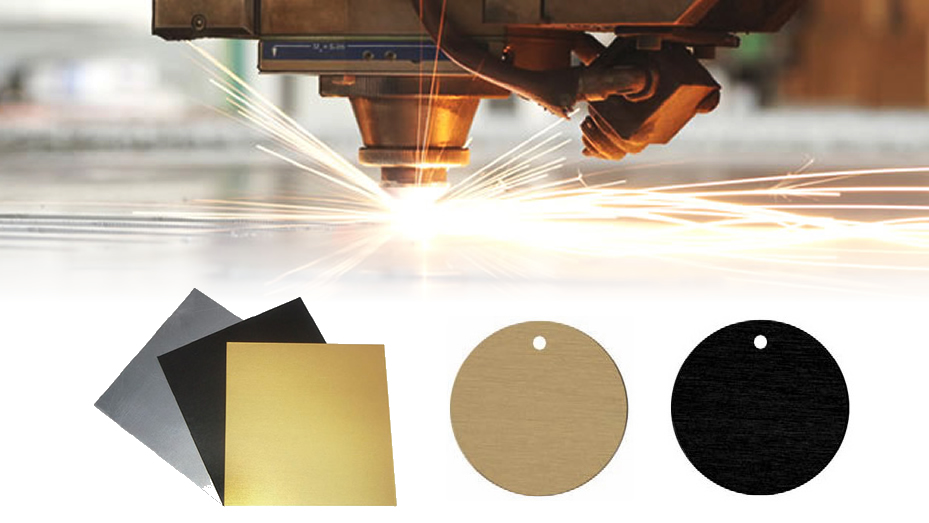

Laserable materials: engraving plates, tags and medals

Laser engraving and cutting are essential technologies in various industries for marking, customization, and component manufacturing. Each material requires specific laser settings to optimize the results. Below is an overview of the most common materials used for laser engraving and cutting on plastic, aluminum, and other types of metal.

Two new inkjet printers for industrial coding applications

We offer two new inkjet printers that are ideal for numerous applications in industrial marking.

The Primo IFL model is suitable for printing logos, alphanumeric text, date/time, batch/expiration numbers, and 1D and 2D barcodes. This Inline 12 inkjet marker stands out for its exceptional connectivity capabilities, a novelty in the landscape of high-resolution industrial inkjet printers (600 dpi): it allows data input via precise touch screen, wireless keyboard, tablet, smartphone, or PC.

Difference between Industrial Lasers and Lasers for Hobbyists

The laser markers are versatile tools used in various sectors, from industrial production to craftsmanship. However, there are significant differences between industrial lasers and hobbyist lasers, both in terms of capabilities and applications.

Laser engraving of wood: cutting and materials

Laser engraving on wood is a technique that allows for precise and detailed engraving of patterns or text. This method uses a laser beam to vaporize the wood in the desired areas, creating an engraving. It is a particularly effective and durable process because it works with high precision and ensures long-lasting results. For these reasons, it is highly valued in both crafts and industry.

Laser Marking and Laser Engraving: differences and similarities

Laser marking and laser engraving are often perceived as synonyms, but they are two different processes. Let's explore the differences and similarities together.

Both processes are used to imprint a permanent mark on a surface using a laser beam.